Innovations in Eco-Friendly Dry Cleaning: Preserving Fabric Integrity Without Shrinkage

In the evolving landscape of textile care, 2025 marks a pivotal year where environmentally conscious dry cleaning intersects with advanced fabric preservation techniques. Traditional dry cleaning methods, often reliant on harsh chemicals such as perchloroethylene (perc), have long risked fabric shrinkage alongside environmental and health concerns. Today, the emergence of eco-friendly dry cleaners that guarantee no shrinkage represents a sophisticated synthesis of chemical-free solvents, temperature-controlled processes, and precision fabric handling. These innovations not only protect delicate garments but also align with global sustainability mandates.

Advanced Solvent Technologies and Their Role in Shrinkage Prevention

The core of shrinkage-free dry cleaning lies in the adoption of plant-based and biodegradable solvents which exhibit gentler interactions with textile fibers. Unlike traditional solvents that can alter fiber structures and cause contraction, modern eco-friendly solvents maintain molecular integrity, thereby preventing dimensional changes. According to a 2023 study published in the Journal of Cleaner Production, the use of green solvents such as liquid carbon dioxide and silicone-based agents drastically reduces fiber stress and the risk of shrinkage, marking a significant advancement in sustainable garment care.

How Does Temperature Regulation Influence Shrinkage in Eco Dry Cleaning?

Temperature control is a critical parameter in preventing fabric shrinkage during dry cleaning. Excessive heat can cause fibers, especially natural ones like wool and cotton, to contract irreversibly. Eco-friendly dry cleaners implement precision thermal management systems that operate within low-temperature thresholds, ensuring that the cleaning process preserves fabric dimensions. This nuanced control, combined with solvent choice, mitigates risks associated with traditional high-heat or aggressive chemical cleaning. For deeper insights on eco-friendly solvent options, refer to plant-based cleaning solvents for fresh fabrics.

Integrating Zero-Waste Practices with Shrinkage-Free Fabric Care

Beyond solvent selection and temperature controls, leading eco dry cleaners incorporate zero-waste methodologies that enhance environmental stewardship while safeguarding garments. These include closed-loop solvent recovery systems and organic stain removal techniques that avoid fiber damage. Such practices are instrumental in maintaining fabric softness and elasticity, critical factors in preventing shrinkage. Explore the intersection of sustainability and garment care at zero-waste dry cleaning revolutionizing fabric care.

What Are the Best Practices for Consumers Seeking Shrinkage-Free, Eco-Friendly Dry Cleaning?

Consumers aiming to protect their wardrobe from shrinkage while embracing eco-consciousness should prioritize dry cleaners that disclose solvent types, temperature protocols, and waste management strategies. Engaging with services that offer specialty garment cleaning using chemical-free methods is advisable, especially for delicate or luxury fabrics. Detailed consumer guides are available at dry cleaner that doesn’t shrink clothes eco methods 2025, offering expert recommendations for sustainable garment care.

Call to Action

For professionals and eco-conscious consumers eager to deepen their expertise in sustainable textile care, exploring specialized content such as specialty garment cleaning with eco-friendly methods and contributing experiential insights can catalyze broader adoption of shrinkage-free, green dry cleaning practices.

Innovative Fabric-Specific Protocols for Shrinkage Prevention in Eco Dry Cleaning

As fabric types diversify with blends and new textile technologies, eco-friendly dry cleaning services are adopting fabric-specific protocols to further minimize shrinkage risks. These protocols involve customized solvent formulas and tailored cycle durations adjusted according to fiber composition. For instance, wool and cashmere receive gentler agitation combined with moisture-optimized solvents to preserve their natural elasticity, while delicate synthetics benefit from carefully calibrated solvent polarity adjustments. Such precision ensures that the cleaning process respects the unique structural attributes of each fabric, enhancing longevity without compromising on environmental standards.

Leveraging AI and Machine Learning to Optimize Eco Dry Cleaning Processes

Emerging technologies such as AI and machine learning are revolutionizing eco-friendly dry cleaning by predicting optimal solvent blends and process parameters that prevent shrinkage. By analyzing historical cleaning data and fabric properties, AI algorithms can customize cleaning cycles dynamically, balancing effective stain removal with minimal fiber stress. This data-driven approach reduces trial-and-error in solvent selection and temperature management, ultimately improving both garment care and sustainability metrics. Leading green dry cleaning enterprises in Tampa and beyond are increasingly integrating these technologies, setting new benchmarks for eco-conscious fabric maintenance.

Can Smart Dry Cleaning Systems Eliminate Shrinkage Risks Completely?

While smart systems offer unprecedented control, the question remains whether they can entirely eliminate shrinkage risks in eco dry cleaning. Factors such as fiber variability, prior garment wear, and environmental conditions introduce complexities that even AI may struggle to fully predict. However, as AI models evolve and incorporate real-time sensor feedback, the prospect of near-zero shrinkage becomes more tangible. Continued interdisciplinary research blending textile science, environmental chemistry, and data analytics is essential to realize this vision. For practical consumer insights, consider reviewing dry cleaner that doesn’t shrink clothes eco methods 2025.

Eco Dry Cleaning Certification Standards and Their Impact on Shrinkage Assurance

Certification standards such as Green Seal and OEKO-TEX are becoming critical markers for consumers seeking assurance that their dry cleaning services employ shrinkage-preventive and environmentally responsible practices. These certifications evaluate solvent safety, waste management, and process consistency, ensuring that eco dry cleaners meet rigorous criteria for fabric care and sustainability. Notably, certified establishments are required to document shrinkage rates and implement corrective measures, fostering transparency and consumer confidence. For a comprehensive exploration of eco dry cleaning certifications, visit non-toxic dry cleaners choosing healthier options.

Consumer Empowerment Through Transparency and Education

Empowering consumers to make informed choices is pivotal in advancing shrinkage-free, eco-friendly dry cleaning. This includes transparent communication about solvent compositions, process temperatures, and ecological footprints. Dry cleaners that educate clients on proper garment care and provide personalized advice on fabric compatibility further enhance garment longevity and sustainability impact. Engaging with educational resources and expert blogs like sustainable garment care protecting luxury wardrobes equips consumers to advocate for safer, greener textile maintenance.

We invite readers to share their experiences with eco-friendly dry cleaning and discuss how these innovative approaches have impacted their fabric care routines. Join the conversation and help foster a community dedicated to sustainable fashion and responsible garment care.

For a deeper dive into the intersection of sustainability and garment care, explore our detailed guide on zero-waste dry cleaning revolutionizing fabric care.

Enzymatic Innovations: Tailoring Eco-Friendly Shrinkage Control at the Molecular Level

Recent breakthroughs in enzymatic fabric treatments showcase a paradigm shift in eco-friendly dry cleaning, focusing on molecular precision to prevent shrinkage. Enzymes, as biocatalysts, selectively target and modify surface impurities and soil without disrupting fiber integrity, contrasting sharply with traditional chemical detergents that risk fiber contraction. For example, cellulase enzymes gently remove fuzz and pills on cotton, enhancing softness and dimensional stability, while proteases assist in breaking down protein-based stains on wool and silk without compromising their natural elasticity.

These enzymatic formulations are biodegradable and derived from sustainable sources, aligning perfectly with the zero-waste ethos. Their integration into dry-cleaning solvent systems or pre-treatment sprays is revolutionizing how delicate garments are refreshed and preserved. The subtle action of enzymes minimizes mechanical agitation requirements, thus further reducing shrinkage potential. This approach is supported by a 2024 report from the Journal of Biotechnology highlighting enzyme efficacy in textile care.

How Do Enzymatic Treatments Compare to Conventional Methods in Preventing Shrinkage?

Enzymatic treatments offer a gentler alternative by targeting specific stains and fabric surface imperfections without degrading fiber strength or causing dimensional changes. Unlike harsh solvents or high-temperature processes that can induce fiber shrinkage, enzymes operate effectively at lower temperatures and neutral pH levels, preserving the natural morphology of the fabric. The precision of enzyme-substrate interactions reduces the risk of over-processing, a common cause of shrinkage in traditional dry cleaning. Furthermore, enzymatic systems often allow for shorter cycle times, thereby lowering exposure to mechanical and thermal stressors.

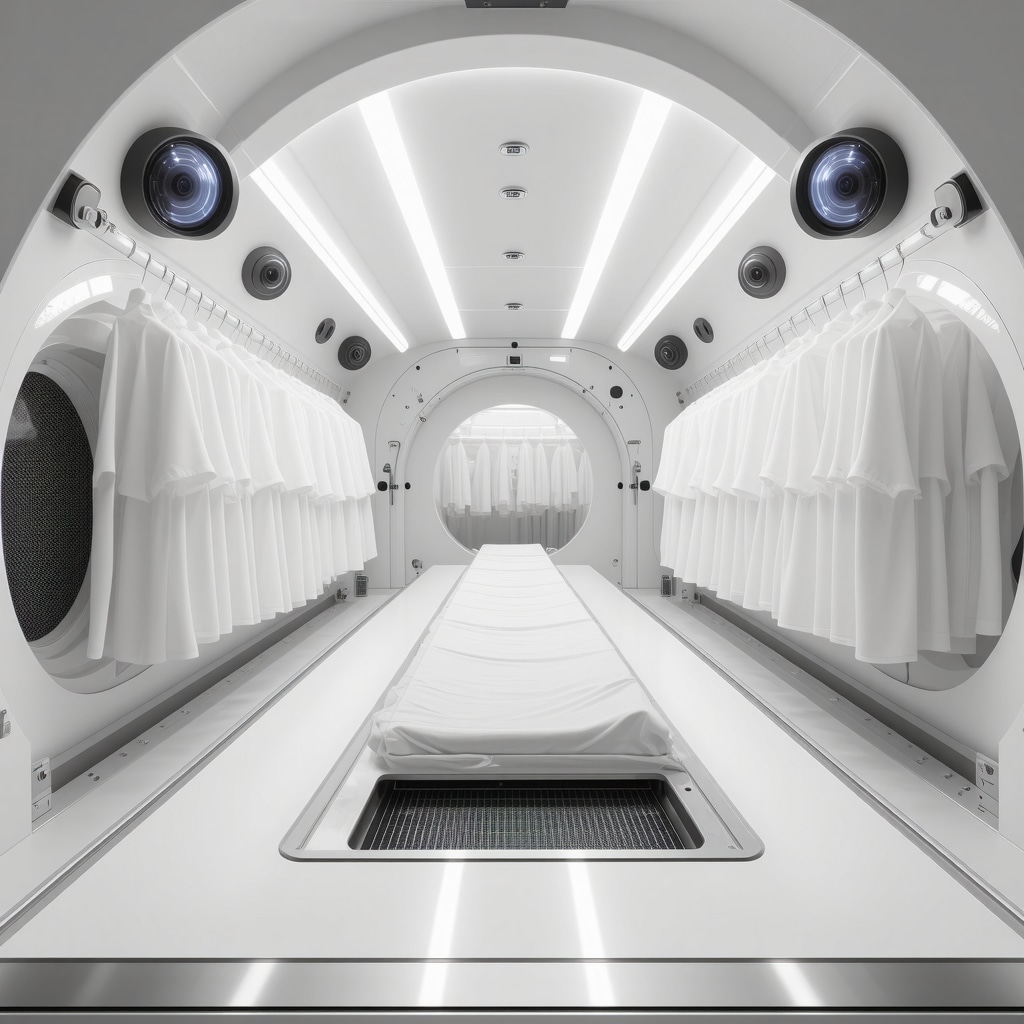

Advanced Sensor Integration for Real-Time Shrinkage Monitoring in Eco Dry Cleaning

Incorporating high-resolution sensors into dry cleaning machinery empowers cleaners to monitor fabric tension, moisture levels, and dimensional changes in real-time. These sensors utilize fiber optic and piezoelectric technologies to detect minute alterations during cleaning cycles, enabling immediate process adjustments to mitigate shrinkage risks. This proactive feedback loop enhances precision, especially in handling complex fabric blends or garments with sensitive finishes.

Leading eco-conscious dry cleaning facilities are adopting these smart monitoring systems to complement AI-driven solvent selection and temperature regulation. The convergence of sensor data and machine learning analytics creates a robust framework for dynamic process control, ensuring garments retain their original fit and texture post-cleaning.

Can Real-Time Sensor Feedback Fully Replace Traditional Quality Control in Dry Cleaning?

While real-time sensor feedback significantly augments process accuracy, it does not entirely supplant traditional quality control measures. Physical inspections remain essential to assess tactile qualities such as hand feel, drape, and subtle fabric nuances that sensors might not fully capture. However, sensor integration reduces reliance on subjective assessments and enhances reproducibility. The synergy between empirical inspection and sensor data fosters a comprehensive quality assurance regime, minimizing shrinkage and other fabric defects.

For professionals eager to deepen their understanding of sensor-enabled eco dry cleaning, resources like smart dry cleaning technology innovation provide cutting-edge insights.

Collaborative Research: Bridging Textile Science and Environmental Chemistry for Next-Gen Shrinkage Solutions

Interdisciplinary research initiatives are pivotal in tackling the multifaceted challenge of fabric shrinkage within eco-friendly dry cleaning frameworks. Collaborative efforts between textile scientists, chemists, and environmental engineers focus on developing novel solvent systems that balance cleaning efficacy with fiber preservation. These projects explore supramolecular solvent assemblies, nanostructured cleaning agents, and bio-inspired fiber stabilizers that mimic natural protective mechanisms.

Moreover, ongoing studies investigate fabric pre-conditioning techniques that reinforce fiber resilience before cleaning, significantly reducing shrinkage vulnerability. This holistic approach leverages advances in polymer chemistry and sustainable material science to design next-generation dry cleaning protocols with minimal ecological footprints.

Engage with ongoing research and contribute to knowledge sharing platforms to stay at the forefront of sustainable textile care innovations.

Join the dialogue on sustainable fabric care and share your experiences with enzymatic treatments or sensor-based dry cleaning technologies. Your insights can drive community learning and foster industry-wide transformation.

Enzymatic Precision: Molecular-Level Control in Sustainable Fabric Care

Building upon enzymatic innovations, recent advancements have refined the integration of bespoke biocatalysts tailored to individual fiber chemistries, optimizing stain removal while preserving dimensional stability. These enzymes, often immobilized on biodegradable nanocarriers, facilitate targeted action that minimizes solvent and mechanical stress. The synergy of enzymatic specificity with eco solvents enhances fabric longevity, especially for complex blends that traditionally posed shrinkage challenges.

How Are Immobilized Enzymes Revolutionizing Shrinkage Prevention in Eco Dry Cleaning?

Immobilized enzymes provide controlled release and reuse capabilities, amplifying process efficiency and environmental benefits. By anchoring enzymes onto carriers, these systems reduce enzyme degradation and allow precise dosing that circumvents fiber overexposure. This approach reduces the need for aggressive chemical adjuncts and mechanical agitation, thereby significantly lowering shrinkage risks. According to a 2024 review in the Journal of Applied Polymer Science, immobilized enzymatic systems exemplify a frontier technology marrying sustainability with superior fabric care.

Smart Sensor Networks: Integrating Multimodal Data for Proactive Shrinkage Mitigation

Beyond single-point sensors, the deployment of distributed sensor networks within dry cleaning units enables a multidimensional real-time assessment of fabric integrity. These networks combine fiber-optic strain gauges, humidity sensors, and thermal cameras to create a comprehensive fabric condition map throughout cleaning cycles. The resulting data streams feed into predictive AI models that dynamically adjust solvent composition, agitation intensity, and drying parameters to preempt shrinkage onset.

The evolution from isolated sensor feedback to integrated sensor ecosystems marks a paradigm shift in textile care precision, unlocking new levels of garment preservation efficacy.

Collaborative Innovation: Cross-Disciplinary Approaches to Next-Gen Eco Dry Cleaning

Cutting-edge developments increasingly rely upon cross-sector collaboration, blending textile engineering, enzymology, environmental chemistry, and data science to devise holistic shrinkage-preventive methods. For instance, the design of supramolecular solvent assemblies inspired by biological membranes enhances selective soil removal while maintaining fiber hydration balance. Concurrently, polymer chemists contribute novel fiber-protective coatings activated during cleaning to reinforce structural integrity.

Expanding Certification Frameworks to Include Molecular and Sensor Innovations

Certification bodies are evolving to incorporate criteria evaluating enzymatic formulations and sensor-enabled process controls. This ensures new technologies meet stringent environmental and fabric care benchmarks, fostering industry-wide adoption. Transparency regarding these advanced methodologies empowers consumers to select services verified for cutting-edge shrinkage prevention and sustainability compliance.

Engage with the Future of Eco-Friendly Dry Cleaning

Professionals and connoisseurs seeking to elevate their understanding of molecular and sensor-driven shrinkage prevention are encouraged to explore the latest literature and technology showcases. Delve deeper at smart dry cleaning technology innovation and participate in forums dedicated to sustainable textile care advancements. Connect, contribute, and champion the next wave of eco-conscious garment maintenance.

Expert Insights & Advanced Considerations

Enzymatic Biocatalysts Redefining Fiber Preservation

Enzymatic treatments have transcended traditional cleaning by offering molecular-level precision that safeguards fabric integrity. Their capability to selectively degrade stains without compromising fiber structure represents a breakthrough in shrinkage prevention, especially for sensitive textiles like wool and silk. This approach aligns with the zero-waste paradigm, reducing reliance on aggressive chemicals and mechanical stress.

Integration of AI and Sensor Networks Enhances Process Adaptability

Combining AI algorithms with distributed sensor networks enables dynamic adjustment of cleaning parameters in real-time, tailored to specific fabric responses. This smart system approach minimizes fiber stress and shrinkage risk by continuously monitoring moisture, tension, and temperature, thus achieving an unprecedented balance between cleaning efficacy and garment care.

Customized Solvent Formulations for Diverse Textile Compositions

Eco-friendly dry cleaning is increasingly moving towards solvent customization based on fabric type and blend. Tailored solvent polarity and agitation levels preserve elasticity and dimensional stability across natural and synthetic fibers, exemplifying a sophisticated strategy to prevent shrinkage while maintaining environmental compliance.

Cross-Disciplinary Collaboration Accelerates Innovation

Progress in shrinkage prevention is propelled by converging expertise from textile science, enzymology, polymer chemistry, and environmental engineering. This synergy fosters the development of bio-inspired solvents and fiber-protective coatings that elevate fabric resilience, heralding a new era of sustainable garment care.

Certification Evolution Encourages Transparency and Consumer Confidence

Emerging certification frameworks now encompass enzymatic and sensor-based technologies, raising industry standards for shrinkage assurance. This evolution enhances consumer trust and promotes accountability among eco dry cleaning providers, catalyzing widespread adoption of advanced sustainable practices.

Curated Expert Resources

Journal of Cleaner Production: Offers comprehensive research on green solvents and sustainable cleaning technologies, essential for understanding eco-friendly dry cleaning advancements.

Journal of Biotechnology: Provides detailed studies on enzymatic applications in textile care, highlighting molecular mechanisms that prevent shrinkage.

Journal of Applied Polymer Science: Explores innovations in immobilized enzyme systems and polymer-based fiber stabilizers relevant to eco dry cleaning.

Smart Dry Cleaning Technology Innovation: A focused resource on integrating AI and sensor technologies for precision fabric care.

Zero-Waste Dry Cleaning Revolutionizing Fabric Care: Explores holistic environmental practices complementing shrinkage prevention.

Final Expert Perspective

The frontier of eco-friendly dry cleaning is defined by its relentless pursuit of shrinkage-free fabric care through innovative molecular, technological, and procedural advancements. Enzymatic precision, AI-driven process optimization, and bespoke solvent formulations collectively transform garment maintenance into a sustainable, high-fidelity craft. As certification standards evolve and interdisciplinary collaborations flourish, stakeholders are empowered to champion a future where ecological responsibility and garment longevity coexist harmoniously. To deepen your expertise and engage with these transformative approaches, explore the insights at smart dry cleaning technology innovation and contribute your professional experiences to advance the field.